Lead Intelligent Equipment (LEAD) has formed a strategic partnership with a major South Korean company to provide cutting-edge equipment for its high-end digital battery cell production line. This collaboration aims to improve the accuracy and efficiency of lithium-ion battery manufacturing, setting new industry standards.

The partnership is a significant milestone for LEAD, marking a breakthrough in digital manufacturing. LEAD has solidified its position as a leader in the technology-driven evolution of lithium-ion battery production. The South Korean partner is a leading battery manufacturer with a large market share in both the electric vehicle (EV) and digital battery industries. It is a key supplier to top-tier automotive and tech brands worldwide.

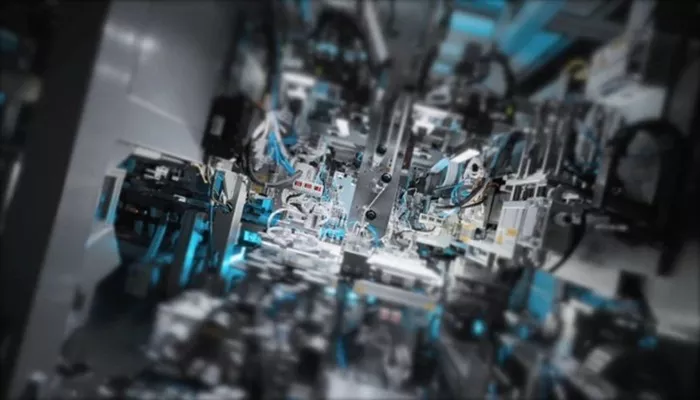

As part of the partnership, LEAD has introduced advanced technology to upgrade the battery manufacturing process. The new integrated cutting and stacking equipment provides impressive technical benefits, setting new benchmarks for the industry. In production trials, LEAD’s equipment demonstrated exceptional cutting precision, achieving a process capability index (CPK) value of over 333, the highest in the industry. Additionally, stacking accuracy surpassed previous standards, ensuring top-tier performance.

The optimized equipment structures have also increased efficiency by 25%. The production of smartphone batteries has reached 5PPM (parts per million), a significant achievement for digital battery manufacturing. By incorporating digital tools such as intelligent commissioning, automation, and data-driven technologies, LEAD has improved process consistency, reduced ramp-up times, and shortened project delivery cycles.

In production tests, the integrated cutting and stacking machine showed outstanding productivity and stability. The LEAD team’s focus on optimization and technical excellence received high praise from the South Korean client, underscoring the value of the collaboration.

Batteries are essential for powering portable, high-performance digital devices. Precision in manufacturing is crucial to improving battery performance, ensuring consumer safety, and lowering production costs.

Yanqing Wang, chairman of LEAD, commented: “Our partnership with the South Korean company has resolved long-standing challenges in high-precision and technical process control, advancing battery performance. With our extensive experience in lithium-ion battery manufacturing, we can provide customized solutions for various industries, including new energy vehicles, consumer electronics, and energy management. This expertise helps manufacturers achieve significant improvements in efficiency, quality, and technology.”