Dana Incorporated showcased a series of significant advancements in its technology and aftermarket service offerings for mobile and industrial mining equipment at the recent MINExpo event.

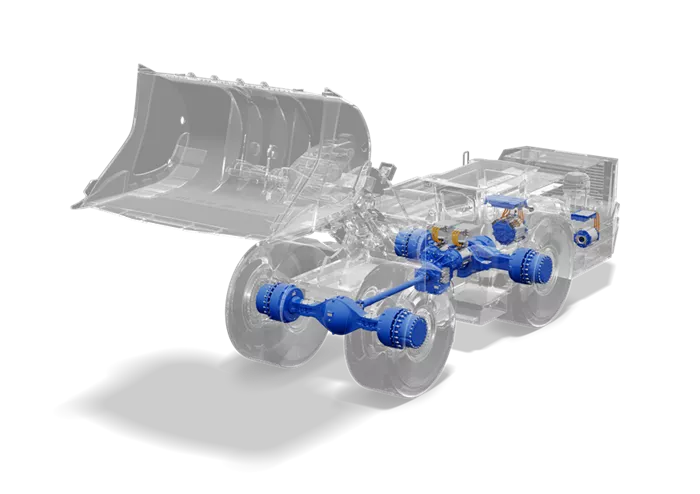

One of the key highlights was the introduction of a hybrid drivetrain system tailored for underground loaders. This innovative system features the Spicer Electrified eSP502 powershift e-Transmission, paired with an on-engine generator, a robust Spicer 20D axle, and Spicer driveshafts, underscoring Dana’s commitment to enhancing efficiency in mining operations.

Additionally, Dana presented a zero-emission drivetrain solution specifically designed for drill rigs and utility vehicles. This solution integrates the new Spicer Electrified eSG101 single-speed e-Gearbox with the Dana TM4 LD HV800 motor/inverter system, promising a remarkable increase in mechanical efficiency. Compared to conventional designs, this combination can achieve up to a 40% improvement in mechanical efficiency at double input speed.

Another notable showcase was the updated Brevini EvoMax helical and bevel-helical gearboxes, intended for mining conveyor applications. The revamped design incorporates a fan within the motor mount bell housing, thus eliminating the need for an external frame. This enhancement not only simplifies installation but also significantly boosts cooling capacity, resulting in a more compact footprint.

For attendees interested in torque solutions, Dana displayed its Brevini planetary gearbox, which offers torque ranges up to 2,200 kNm, making it suitable for apron feeders, roller presses, and other applications.

Furthermore, Dana introduced its new Certified Reman program for Dana Spicer drive components utilized in mining and other off-highway sectors. This program is designed to restore Dana Spicer off-highway axles, transmissions, torque converters, and gearboxes to the same performance standards as new units from the factory. It promises shorter delivery times and competitive pricing, reflecting Dana’s commitment to value.

Currently operational at Dana facilities across Europe, the Certified Reman program is set to expand to an additional 50 locations throughout North America, Europe, the Middle East, Africa, and China by the end of 2025. Approved service centers will undergo evaluation against more than 20 criteria to ensure they meet Dana’s stringent standards for performance, value, ethics, sustainability, and social responsibility.

Related topics:

- Three Mile Island Nuclear Unit to Reopen, Powering Microsoft Data Centers with Clean Energy

- Groundbreaking AI-Driven Autonomous Underwater Vehicle Inspects Scottish Wind Farm

- Countdown to the 2024 Power Progress Summit: One Week Left to Register!