Diesel generators have become an essential power source for various applications, from residential backup systems to industrial-scale energy solutions. Their reliability, efficiency, and longevity make them a preferred choice for those needing uninterrupted power supply. But how does a diesel generator work? In this comprehensive article, we will explore the inner workings of diesel generators, their components, operational principles, and advantages.

By the end, you’ll have a clear understanding of how diesel generators generate electricity and why they are such a popular choice in various settings.

Understanding Diesel Generators: An Overview

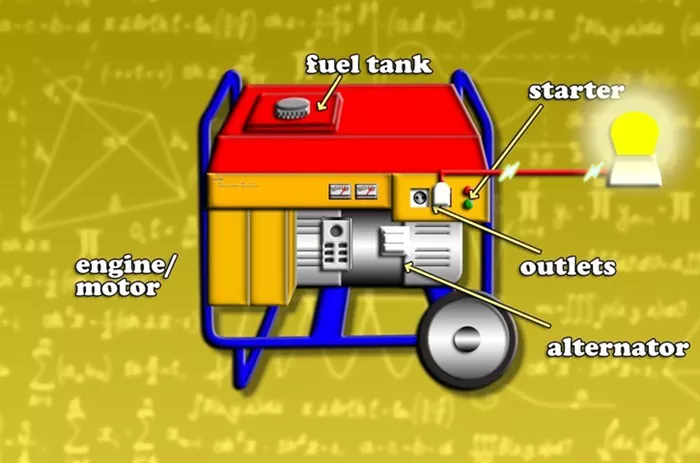

A diesel generator is a combination of a diesel engine and an electric generator, commonly known as an alternator. This powerful machine converts mechanical energy produced by the diesel engine into electrical energy.

Key Components of a Diesel Generator

To understand how a diesel generator works, it is essential to recognize its primary components:

- Diesel Engine: The heart of the generator, which burns diesel fuel to create mechanical energy.

- Alternator: The component that converts mechanical energy from the engine into electrical energy.

- Fuel System: Responsible for delivering diesel fuel to the engine.

- Cooling System: Maintains optimal operating temperature by dissipating heat generated during operation.

- Lubrication System: Reduces friction between moving parts, enhancing the engine’s efficiency and lifespan.

- Control Panel: Provides operational controls, monitoring capabilities, and safety functions.

Understanding these components will provide insights into the generator’s functionality and efficiency.

How Do Diesel Generators Operate?

The Diesel Combustion Process

The operation of a diesel generator begins with the diesel engine. The engine functions on the principle of compression ignition, which is different from gasoline engines that use spark ignition.

- Air Intake: The engine draws in air through an air filter.

- Compression: The air is compressed to a high pressure and temperature within the engine cylinder.

- Fuel Injection: Diesel fuel is injected directly into the highly compressed air at the end of the compression stroke.

- Combustion: The heat generated from the compression ignites the injected diesel fuel, causing a rapid expansion of gases. This explosion drives the piston downward, generating mechanical energy.

Mechanical Energy to Electrical Energy

Once the diesel engine generates mechanical energy, this energy needs to be converted into electrical energy.

- Crankshaft Rotation: The piston’s downward motion turns the crankshaft, which is connected to the alternator.

- Alternator Function: As the crankshaft rotates, it spins the rotor inside the alternator. The rotor is surrounded by a magnetic field, which induces an electric current in the stator windings, effectively converting mechanical energy into electrical energy.

- Output Voltage Regulation: The generated electricity is typically alternating current (AC). The voltage and frequency of this electricity can be regulated by adjusting the engine speed and the alternator’s output.

Power Distribution

Once the electricity is generated, it needs to be distributed effectively:

- Control Panel: The control panel monitors the generator’s performance, allowing users to start and stop the generator and adjust settings as necessary.

- Load Connection: The generated electricity can be connected to various loads, such as residential appliances, industrial machinery, or backup power systems, depending on the application.

Advantages of Diesel Generators

Diesel generators have several advantages that contribute to their popularity across various sectors.

Fuel Efficiency

Diesel engines are known for their superior fuel efficiency compared to gasoline engines. Diesel generators can operate for extended periods on a relatively small amount of fuel, making them ideal for long-term power needs.

Durability and Longevity

Diesel engines are built to withstand heavy loads and rigorous usage, resulting in a longer lifespan. With proper maintenance, diesel generators can last for many years, making them a sound investment for continuous power supply.

High Power Output

Diesel generators can provide substantial power outputs, making them suitable for industrial applications where large amounts of energy are required. Their ability to handle heavy loads makes them a reliable choice for critical power applications.

Lower Operating Costs

Although diesel fuel prices fluctuate, diesel generators tend to have lower operating costs over time due to their fuel efficiency and durability. This aspect makes them an economically viable solution for businesses and industries.

Common Applications of Diesel Generators

Diesel generators are versatile and can be employed in various settings:

Residential Backup Power

Many homeowners invest in diesel generators for emergency power supply during outages. They provide reliable electricity for essential appliances, ensuring comfort and safety.

Construction Sites

Diesel generators are commonly used at construction sites where access to the electrical grid is limited. They power tools, lighting, and equipment, enabling continuous work without interruptions.

Industrial Applications

In industries requiring constant energy, diesel generators serve as prime power sources or backup solutions. Their ability to handle high loads makes them ideal for factories and manufacturing plants.

Remote Locations

Diesel generators are invaluable in remote areas lacking electrical infrastructure. They provide power for telecommunications, mining operations, and research stations.

Environmental Considerations

While diesel generators offer numerous advantages, they also have environmental impacts that cannot be overlooked.

Emissions

Diesel engines produce greenhouse gases and pollutants, including nitrogen oxides (NOx) and particulate matter. Regulatory standards dictate emissions levels, prompting manufacturers to develop cleaner technologies and solutions.

Noise Pollution

Diesel generators can be noisy during operation, posing a concern in residential areas or quiet environments. Soundproof enclosures and advanced muffling techniques can help reduce noise levels.

Fuel Spills and Contamination

Handling diesel fuel requires caution to prevent spills and contamination. Proper storage and maintenance protocols can mitigate these risks and protect the environment.

Innovations in Diesel Generator Technology

The diesel generator market is evolving, with ongoing innovations aimed at improving performance and sustainability.

Hybrid Systems

Combining diesel generators with renewable energy sources, such as solar or wind, creates hybrid systems that optimize efficiency and reduce emissions. These systems can provide reliable power while minimizing reliance on fossil fuels.

Advanced Control Systems

Modern diesel generators incorporate advanced control systems for better efficiency and monitoring. These systems allow for remote access, predictive maintenance, and performance optimization.

Cleaner Combustion Technologies

Technological advancements are leading to cleaner combustion processes, reducing emissions and improving the overall environmental impact of diesel generators.

Maintenance and Care for Diesel Generators

To ensure optimal performance and longevity, proper maintenance of diesel generators is essential.

Regular Inspections

Routine inspections should include checking fluid levels, filters, and electrical connections. Identifying potential issues early can prevent costly repairs and downtime.

Fuel Quality

Using high-quality diesel fuel is critical for efficient operation. Contaminated fuel can lead to engine problems and reduced performance.

Cleaning and Lubrication

Keeping the generator clean and well-lubricated helps minimize wear and tear on components. Regular cleaning of air filters and external surfaces is essential.

Scheduled Servicing

Adhering to a maintenance schedule, as outlined by the manufacturer, ensures that the generator operates smoothly and efficiently.

see also: How Long Can a Diesel Generator Run Continuously?

Conclusion

In summary, diesel generators operate by converting mechanical energy from a diesel engine into electrical energy through an alternator. Their robust design, fuel efficiency, and high power output make them a preferred choice for various applications, including residential backup, construction, and industrial use.

While they come with environmental considerations, ongoing innovations and technological advancements are addressing these challenges, enhancing the sustainability of diesel generator technology.

Understanding the operational principles and maintenance requirements of diesel generators allows users to maximize their efficiency and longevity, ensuring reliable power when it is needed most.

FAQs:

What is the lifespan of a diesel generator?

The lifespan of a diesel generator can range from 10,000 to 30,000 hours of operation, depending on usage and maintenance practices.

How often should a diesel generator be serviced?

Diesel generators should be serviced regularly, typically every 200 to 500 hours of operation or as recommended by the manufacturer.

Can diesel generators run on biodiesel?

Many diesel generators can operate on biodiesel or biodiesel blends, but it is essential to check compatibility with the manufacturer’s specifications.

What is the difference between standby and prime diesel generators?

Standby generators are designed to provide power during outages, while prime generators are intended for continuous use in off-grid applications.

Are diesel generators safe to operate indoors?

Diesel generators should not be operated indoors due to the risk of carbon monoxide buildup. Adequate ventilation is necessary to ensure safe operation.

Related topics:

- How Long Does a Diesel Generator Last?

- Can a Diesel Generator Operate Using Heating Oil?

- How Long Does Diesel Last in a Generator?