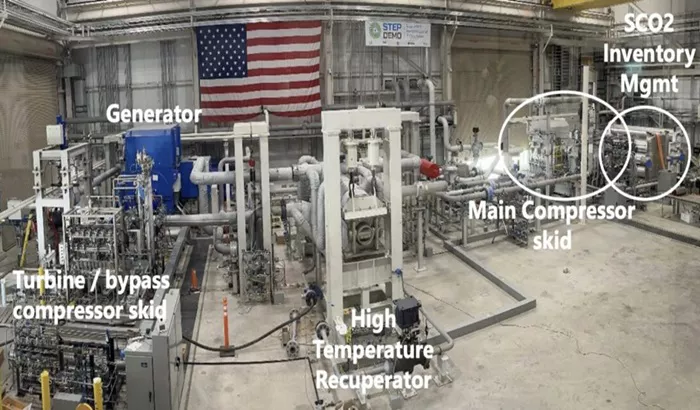

The Supercritical Transformational Electric Power (STEP) Demo pilot plant in San Antonio, Texas, has achieved a major milestone by completing Phase 1 of its 10-MW supercritical carbon dioxide (sCO₂) power cycle project. This $169 million initiative, the largest of its kind, has successfully demonstrated a next-generation indirect sCO₂ Brayton cycle at a 10-MW scale, signaling its readiness for commercial applications.

Developed by GTI Energy in partnership with the Southwest Research Institute (SwRI), the project has reached significant technical milestones, including running the turbine at a full speed of 27,000 RPM at 500°C and 250 bar pressure, generating 4 MW of grid-synchronized power. This data will be instrumental in optimizing future sCO₂ power systems, paving the way for sustainable and efficient energy solutions. “The success of this project underscores the potential of sCO₂ technology to transform the future of power generation,” stated Don Stevenson, GTI Energy’s vice president of carbon management and conversion.

Phase 2 of the project, scheduled for 2025, will see the plant reconfigured to a Recompression Brayton Cycle (RCBC) setup, raising the turbine inlet temperature to 715°C. This phase will enhance the system’s efficiency, allowing it to support a variety of low-emission power generation sources such as solar thermal, nuclear, and carbon-captured biomass.

sCO₂: An Advanced Cycle with Commercial Potential

sCO₂ power cycles, which convert heat to power using supercritical CO₂, offer higher efficiencies than traditional steam-based systems. Operating above 31°C and 7.4 MPa, sCO₂ acts as a dense, compressible fluid, allowing for smaller turbomachinery and reduced water use. The STEP Demo facility has successfully demonstrated a simple Brayton cycle and will transition to an RCBC configuration in Phase 2, aiming to surpass 50% thermodynamic efficiency.

Launched in 2013, the project is backed by the U.S. Department of Energy and has involved overcoming significant engineering challenges. These include developing world-first components such as the largest printed circuit heat exchanger and Inconel 725 piping installation. Specialized techniques for inspecting turbine blades and managing extreme operational conditions were also developed to advance the technology’s readiness level.

Global Partnerships and Future Applications

The STEP Demo has received $125 million in funding from the DOE and partnerships with major energy organizations, including GE Vernova and the National Energy Technology Laboratory. The pilot project also benefits from international collaboration, with partners from Canada, Australia, and France contributing to the development.

sCO₂ technology holds promise for applications ranging from waste heat recovery to utility-scale power generation. However, the industry faces challenges, such as the high costs associated with high-pressure components. Yet, its adaptability to various heat sources and smaller plant footprint make it attractive for industrial and gas turbine retrofits. As sCO₂ cycles continue to evolve, they are set to play a crucial role in developing more sustainable power solutions for the future.

Projects like the NET Power plant in Texas, which is slated to use the Allam-Fetvedt sCO₂ cycle, demonstrate the technology’s scalability, with the Odessa site expected to come online between 2027 and 2028. Meanwhile, Sandia National Laboratories and companies like Echogen Power Systems continue to explore sCO₂’s potential in concentrated solar power and industrial settings.

“This is the largest-scale demonstration of sCO₂ technology to date,” said John Crane of NETL’s Advanced Turbines Technology. “It demonstrates a scalable pathway to larger applications, validating the technology for widespread commercial use.”

The STEP Demo’s achievements highlight the transformative potential of sCO₂ cycles, offering a sustainable and efficient alternative for the future of energy.

Related topics:

- China Unveils World’s Largest Onshore Wind Turbine: A 15-MW Engineering Marvel

- Hydrogen Revolution: AMTA Unveils Groundbreaking Fuel Cell Electric Truck Prototype

- $7 Billion Hydrogen Investment to Propel U.S. Decarbonization Efforts