When it comes to ensuring that your Generac whole house generator is functioning optimally, regular testing is a crucial component of maintenance. These generators are designed to provide backup power during outages, but like any mechanical device, they require periodic checks to confirm that all systems are operational. In this guide, we will walk you through the steps to effectively test your Generac generator, ensuring it’s ready to perform when you need it most.

Understanding the Importance of Testing Your Generator

Generators are an investment in your home’s safety and comfort, particularly during power outages caused by storms, equipment failures, or other unforeseen events. Regular testing not only ensures that your generator can provide reliable power but also helps identify potential issues before they become serious problems.

Testing your Generac generator involves several steps, including routine maintenance checks, load testing, and monitoring of operational performance. By following a consistent testing schedule, you can enhance the lifespan of your generator and ensure that it operates at peak efficiency.

Types of Generac Generators

Generac offers a variety of whole house generators, each with unique features and specifications. Understanding the type of generator you have will help tailor your testing process. Here are the main types:

Air-Cooled Generators

Air-cooled generators are typically used in residential settings and are suitable for homes with moderate power needs. They rely on a fan to circulate air for cooling during operation.

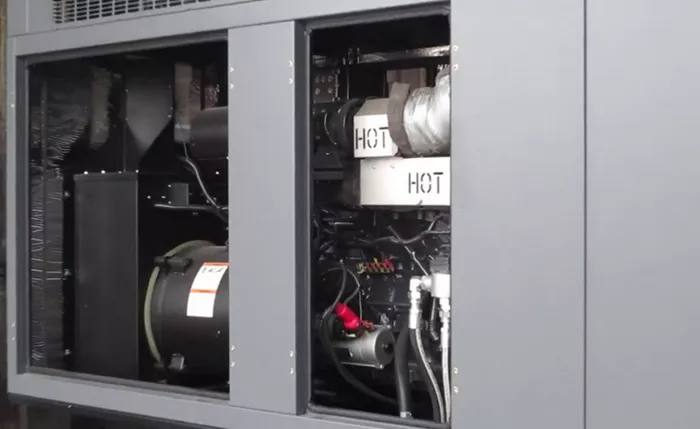

Liquid-Cooled Generators

Liquid-cooled generators are designed for larger power needs and typically serve larger homes or commercial applications. These generators utilize a liquid cooling system to maintain optimal operating temperatures.

Standby Generators

Standby generators automatically detect power outages and engage without any user intervention. They are typically connected to a natural gas or propane line, providing continuous power during outages.

Preparing for the Testing Process

Before testing your Generac whole house generator, there are several preparatory steps to ensure a safe and effective process.

Gather Required Tools and Equipment

Having the right tools on hand will streamline the testing process. The following items are essential:

- Digital multimeter: For voltage testing.

- Load bank: If available, to simulate electrical loads.

- Flashlight: For visibility in dimly lit areas.

- Safety gear: Including gloves and safety glasses.

- Owner’s manual: For reference on specific operational instructions.

Ensure Safety Precautions

Safety should always be your top priority when working with generators. Follow these guidelines:

- Turn off the main power: Always switch off the main power supply before starting any testing procedures.

- Work in a well-ventilated area: Generators can emit harmful gases, so ensure proper ventilation.

- Check for leaks: Inspect the fuel lines and connections for leaks before starting the generator.

Performing Routine Maintenance Checks

Regular maintenance checks are crucial for ensuring your generator’s reliability. Before performing a test, inspect the following components:

Fuel System

- Check fuel levels: Ensure the fuel tank is full. Low fuel levels can lead to improper operation.

- Inspect fuel lines: Look for signs of wear, cracking, or leaks. Replace any damaged lines immediately.

Oil Levels

- Check oil levels: Use the dipstick to confirm that oil levels are within the recommended range. Low oil can cause severe engine damage.

- Change oil: If it’s been over the recommended interval, change the oil according to the manufacturer’s specifications.

Battery Health

- Inspect the battery: Check for corrosion on the battery terminals and ensure the connections are secure.

- Test battery voltage: Use a multimeter to measure the battery’s voltage, ensuring it is within the normal operating range.

Air Filter

- Examine the air filter: A clean air filter is vital for optimal engine performance. Replace it if it appears dirty or clogged.

Conducting a Load Test

A load test is essential for determining whether your generator can handle its maximum rated capacity. This test simulates real-world conditions to ensure that your generator can support the load of your household appliances.

Preparing for the Load Test

- Connect a Load Bank: If available, connect a load bank to the generator to simulate electrical demand. Load banks can help assess the generator’s performance under various load conditions.

- Manual Load Testing: If a load bank isn’t available, you can conduct a manual load test by plugging in essential appliances such as refrigerators, air conditioners, or lights.

Performing the Load Test

- Start the Generator: Turn on your Generac generator and allow it to warm up for a few minutes.

- Apply Load: Gradually apply load by connecting appliances or using the load bank. Monitor the generator’s performance as the load increases.

- Observe Voltage and Frequency: Use the multimeter to check that voltage and frequency remain stable during the load test. The generator should maintain output close to its rated specifications.

Evaluating Performance

- Monitor Performance Metrics: During the load test, keep an eye on performance metrics such as engine temperature, oil pressure, and exhaust emissions. If any metrics fall outside the manufacturer’s specifications, it may indicate a problem that requires attention.

- Check for Unusual Noises: Listen for any unusual sounds coming from the generator during the load test. Strange noises could signify mechanical issues.

Testing Automatic Transfer Switch (ATS)

If your Generac generator includes an automatic transfer switch, it’s vital to test this component as well. The ATS ensures a seamless transition from utility power to generator power during outages.

Testing the ATS Functionality

- Simulate a Power Outage: Turn off the main power supply to simulate a power outage. This action will trigger the ATS to switch to generator power.

- Monitor the Transition: Observe how quickly the ATS engages and whether the generator starts without issues. A properly functioning ATS should switch within seconds.

- Restore Utility Power: Once the generator is running, restore the main power and observe the ATS as it transitions back to utility power. The switch should disengage from the generator and reconnect to the grid seamlessly.

Troubleshooting Common Issues

During the testing process, you may encounter some common issues. Here are a few troubleshooting steps to consider:

Generator Won’t Start

- Check Fuel Levels: Ensure there is adequate fuel in the tank.

- Inspect Battery: Confirm that the battery is charged and connections are secure.

- Review Safety Switches: Make sure all safety switches and circuit breakers are in the proper position.

Poor Performance Under Load

- Inspect Fuel System: Look for clogged fuel filters or fuel line issues.

- Check Oil Levels: Low oil can affect performance; make sure levels are adequate.

- Examine Air Filter: A dirty air filter can restrict airflow, impacting performance.

ATS Not Functioning

- Inspect Connections: Check all electrical connections for loose or corroded terminals.

- Test Voltage: Ensure that the ATS is receiving power and that the voltage is stable.

- Consult Owner’s Manual: Refer to the manual for specific troubleshooting steps related to the ATS.

Documenting Your Testing Process

Keeping a detailed record of your generator testing process is essential for effective maintenance. Documentation helps track performance trends, identifies recurring issues, and ensures that you stay on top of necessary repairs.

Creating a Maintenance Log

- Record Test Dates: Log the date of each test, including routine maintenance checks and load tests.

- Note Performance Metrics: Write down critical performance metrics observed during testing, such as voltage, frequency, and temperature.

- Document Any Issues: Make a note of any issues encountered and the steps taken to resolve them.

See also: 6 Best Quiet Whole House Generators

Conclusion

Regularly testing your Generac whole house generator is crucial for ensuring its reliability during power outages. By understanding the different types of Generac generators, preparing for testing, conducting routine maintenance checks, performing load tests, and documenting your findings, you can keep your generator operating efficiently.

Ultimately, being proactive in testing and maintenance will provide you with peace of mind, knowing that your backup power system is ready to protect your home and family when the lights go out.

FAQs:

How often should I test my Generac generator?

It’s recommended to test your Generac generator at least once a month and conduct a load test every six months to ensure optimal performance.

Can I run my generator without load during testing?

While it is possible to run your generator without load, it is not recommended for extended periods. Always perform load tests to assess the generator’s performance under real-world conditions.

What should I do if my generator fails to start?

If your generator fails to start, check the fuel levels, battery connections, and ensure that all safety switches are in the correct position. Refer to your owner’s manual for troubleshooting tips.

Is it necessary to hire a professional for generator testing?

While some homeowners may feel comfortable testing their generators, hiring a professional is advisable for comprehensive testing and maintenance, especially if any issues arise.

How long can a Generac generator run continuously?

Most Generac generators can run continuously for up to 24 hours, depending on fuel levels and load demands. Always refer to the owner’s manual for specific operating guidelines.

Related topics:

- How Much Propane Does a 22 Kw Generator Use?

- Can a Portable Generator Power the Whole House?

- 7 Best Portable Whole House Generators