Hydraulic generators are an innovative power solution used in various applications, from industrial machinery to off-grid energy systems. They harness the power of hydraulic fluid under pressure to generate electricity, providing an efficient and compact energy source. Unlike traditional generators powered by internal combustion engines or turbines, hydraulic generators rely on the hydraulic power from existing machinery or systems.

This article explains the working principles of hydraulic generators, their components, advantages, and applications, along with insights into their efficiency and maintenance.

Introduction to Hydraulic Generators

Hydraulic generators convert mechanical energy from a hydraulic system into electrical energy. They are commonly used where hydraulic systems already exist, such as in construction equipment, agricultural machinery, and marine vessels. These generators offer a portable and reliable energy source, making them suitable for remote operations and environments where traditional generators may be impractical.

Key Components of a Hydraulic Generator

To understand how hydraulic generators work, it’s essential to identify their primary components:

1. Hydraulic Motor

The hydraulic motor is the core component that converts hydraulic energy into mechanical energy. It operates by using pressurized hydraulic fluid supplied from a hydraulic pump.

2. Generator Unit

The generator unit, attached to the hydraulic motor, converts the mechanical energy into electrical energy. This is typically done using a rotating alternator or similar mechanism.

3. Hydraulic Pump

The hydraulic pump supplies pressurized fluid to the hydraulic motor. It is often driven by another power source, such as an engine or another hydraulic system.

4. Control Valves and Circuitry

Control valves regulate the flow and pressure of the hydraulic fluid, ensuring the motor operates efficiently. Advanced systems may include electronic controls for precise adjustments.

5. Hydraulic Fluid Reservoir

This component stores and supplies hydraulic fluid to the system. Maintaining the fluid at optimal levels is critical for smooth operation.

6. Cooling System

Hydraulic systems generate heat during operation. Cooling mechanisms, such as heat exchangers, maintain the temperature within safe limits to prevent overheating.

The Working Principle of Hydraulic Generators

Hydraulic generators work by harnessing the power of pressurized hydraulic fluid. Here’s how the process unfolds:

Pressurization of Hydraulic Fluid

The hydraulic pump draws hydraulic fluid from the reservoir and pressurizes it. This fluid is then directed to the hydraulic motor through control valves.

Energy Conversion in the Hydraulic Motor

The pressurized fluid enters the hydraulic motor, causing its internal components to rotate. This rotation converts the fluid’s hydraulic energy into mechanical energy.

Electrical Energy Generation

The mechanical energy from the motor drives the generator unit. The generator’s alternator or similar mechanism rotates, producing electrical power.

Regulation and Output

Control systems regulate the generator’s output, ensuring a steady and reliable supply of electricity. These controls also protect the system from overloads or irregularities.

Return of Hydraulic Fluid

After powering the motor, the hydraulic fluid returns to the reservoir, where it is cooled and reused. This closed-loop system enhances efficiency and reduces fluid waste.

Types of Hydraulic Generators

Hydraulic generators come in various designs, tailored for specific applications. Some common types include:

1. Fixed-Displacement Hydraulic Generators

These generators have a fixed hydraulic motor displacement, providing consistent power output. They are ideal for applications requiring a stable and predictable energy supply.

2. Variable-Displacement Hydraulic Generators

Variable-displacement generators allow adjustments to the hydraulic motor’s displacement, enabling flexible power output. This type is suitable for dynamic environments with varying power demands.

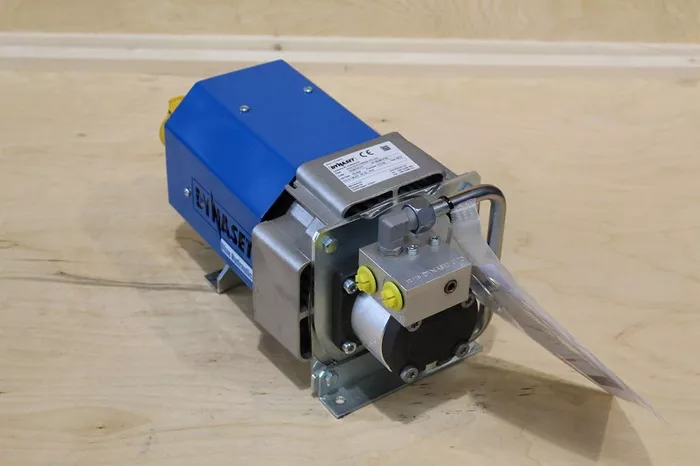

3. Integrated Hydraulic Generators

Integrated systems combine the hydraulic motor and generator unit into a single compact assembly. They are commonly used in space-constrained applications.

4. Standalone Hydraulic Generators

Standalone systems function independently, often as portable units. They can be connected to existing hydraulic systems for temporary or emergency power needs.

Applications of Hydraulic Generators

Hydraulic generators are versatile and find applications in various industries. Here are some prominent use cases:

1. Construction and Heavy Equipment

Hydraulic generators power tools and machinery on construction sites, where hydraulic systems are already in use. They are used for lighting, welding equipment, and other electrical tools.

2. Agriculture

In farming operations, hydraulic generators are used with tractors and harvesters. They provide power for irrigation systems, grain dryers, and other electrical needs.

3. Marine Industry

Marine vessels equipped with hydraulic systems use hydraulic generators for onboard power. These systems are compact and can operate efficiently in confined spaces.

4. Off-Grid and Remote Locations

Hydraulic generators are ideal for off-grid locations, such as mining sites and remote research stations. They provide reliable power in areas without access to traditional electricity.

5. Emergency and Backup Power

Hydraulic generators serve as backup power sources in emergencies, ensuring critical systems continue to operate during outages.

Advantages of Hydraulic Generators

Hydraulic generators offer several benefits over traditional generators. These advantages make them a popular choice for specific applications:

1. Compact and Lightweight

Hydraulic generators are more compact and lighter than conventional diesel or gas generators, making them easier to transport and install.

2. High Efficiency

These generators utilize existing hydraulic systems, reducing energy losses and increasing overall efficiency. They provide power on demand without requiring a separate engine.

3. Reliability

Hydraulic generators are known for their durability and reliable performance. They can operate under harsh conditions and handle continuous usage.

4. Low Maintenance Requirements

With fewer moving parts and simplified designs, hydraulic generators require less maintenance than traditional generators.

5. Reduced Noise and Emissions

Hydraulic generators produce less noise and fewer emissions compared to internal combustion generators, making them environmentally friendly and suitable for noise-sensitive environments.

6. Scalability

Hydraulic generators can be scaled up or down depending on the power requirements, offering flexibility for various applications.

Limitations of Hydraulic Generators

Despite their advantages, hydraulic generators have some limitations:

1. Dependency on Hydraulic Systems

Hydraulic generators require an existing hydraulic system to function. This limits their use in settings without hydraulic infrastructure.

2. Initial Cost

The initial investment for hydraulic generators may be higher than traditional generators, particularly for integrated or specialized systems.

3. Complexity in Setup

Setting up a hydraulic generator involves integrating it with the hydraulic system, which may require skilled personnel and specialized equipment.

Maintenance of Hydraulic Generators

Regular maintenance ensures the longevity and performance of hydraulic generators. Key maintenance practices include:

Checking Hydraulic Fluid Levels

Ensure the hydraulic fluid is at the recommended level and replace it if contaminated.

Inspecting Hoses and Connections

Regularly inspect hoses and connections for leaks, cracks, or wear.

Cleaning Filters

Replace or clean hydraulic filters to prevent blockages and maintain fluid quality.

Monitoring System Pressure

Check the hydraulic system’s pressure to ensure it operates within safe limits.

Servicing the Generator Unit

Periodically inspect the generator unit for wear and perform routine maintenance, such as bearing lubrication.

Conclusion

Hydraulic generators are a reliable and efficient solution for generating electricity, especially in environments where hydraulic systems already exist. By leveraging pressurized hydraulic fluid, these generators provide a compact, versatile, and cost-effective energy source. Their applications span multiple industries, offering benefits like high efficiency, low maintenance, and environmental sustainability.

Understanding how hydraulic generators work and their benefits empowers users to make informed decisions, ensuring optimal performance and cost savings. With ongoing advancements in technology, hydraulic generators will continue to play a vital role in modern power systems.

Related Topics

- What Size Generator Do I Need For My RV?

- How Does A Generator Circuit Breaker Work?

- Do Generators Take Regular Gas?