Installing an AC compressor is a critical part of ensuring your air conditioning system works efficiently. While the cost of the compressor itself is a significant expense, labor costs can also add up. In this article, we’ll break down everything you need to know about labor costs for AC compressor installation, including factors that influence pricing, average costs, and tips to save money.

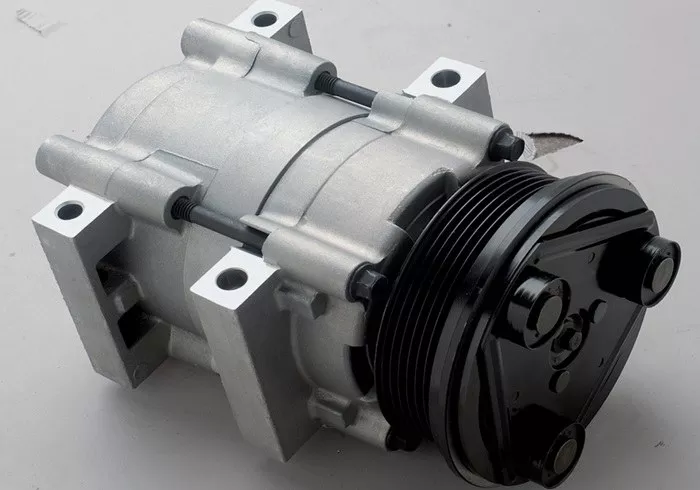

What is an AC Compressor?

An AC compressor is the heart of your air conditioning system. It compresses refrigerant gas, which is essential for cooling your home. Without a functioning compressor, your AC unit won’t be able to cool the air effectively.

Why Labor Costs Matter

Labor costs are a major part of the total expense when installing an AC compressor. Skilled technicians are required to handle the installation, which involves electrical work, refrigerant handling, and precise measurements. Understanding labor costs can help you budget better and avoid surprises.

Factors Affecting Labor Costs

1. Type of AC System

The type of AC system you have can impact labor costs. Central air systems, ductless mini-splits, and window units all have different installation requirements. Central air systems typically require more labor due to their complexity.

2. Compressor Size and Capacity

Larger compressors or those with higher capacity may require more time and effort to install. This can increase labor costs.

3. Location of the Compressor

If the compressor is located in a hard-to-reach area, such as a rooftop or tight crawl space, installation will take longer and may cost more.

4. Existing System Condition

If your existing AC system is old or in poor condition, additional work may be needed to prepare it for the new compressor. This can include cleaning, repairs, or upgrades.

5. Local Labor Rates

Labor costs vary by region. Urban areas with higher living costs typically have higher labor rates compared to rural areas.

6. Time of Year

During peak cooling seasons, HVAC technicians are in high demand. This can lead to higher labor costs. Scheduling installation during the off-season may save you money.

Average Labor Costs for AC Compressor Installation

Central Air Conditioning Systems

For central air systems, labor costs typically range from 51,500. This includes removing the old compressor, installing the new one, and testing the system.

Ductless Mini-Split Systems

Ductless systems are generally easier to install, with labor costs ranging from 300 to 800.

Window Units

Window units are the simplest to install, with labor costs usually between 1300.

Additional Costs to Consider

1. Refrigerant

If your system needs additional refrigerant, this can add to the overall cost. Refrigerant costs range from 150 per pound.

2. Permits and Inspections

Some areas require permits and inspections for AC installations. These can cost between 1300.

3. Disposal of Old Equipment

Disposing of the old compressor may incur additional fees, typically ranging from 5150.

How to Save on Labor Costs

1. Get Multiple Quotes

Always get quotes from at least three different HVAC contractors. This will help you find the best price and ensure you’re not overpaying.

2. Schedule During Off-Peak Seasons

As mentioned earlier, scheduling installation during the off-season can save you money.

3. Choose Energy-Efficient Models

While energy-efficient compressors may have a higher upfront cost, they can save you money in the long run through lower energy bills.

4. Maintain Your System

Regular maintenance can extend the life of your AC system and reduce the likelihood of costly repairs or replacements.

DIY vs. Professional Installation

Why Professional Installation is Recommended

Installing an AC compressor is not a DIY job. It requires specialized knowledge, tools, and certifications. Improper installation can lead to system failure, safety hazards, and voided warranties.

Risks of DIY Installation

Attempting to install a compressor yourself can result in:

- Electrical hazards

- Refrigerant leaks

- Damage to the compressor or other components

- Voided manufacturer warranty

How to Choose the Right HVAC Contractor

1. Check Credentials

Ensure the contractor is licensed, insured, and certified by organizations like NATE (North American Technician Excellence).

2. Read Reviews

Look for online reviews and ask for references to gauge the contractor’s reputation.

3. Ask About Warranties

A reputable contractor will offer warranties on both labor and equipment.

4. Get a Written Estimate

Always get a detailed, written estimate before work begins. This should include labor costs, materials, and any additional fees.

Conclusion

Labor costs for AC compressor installation can vary widely depending on several factors, including the type of system, location, and local labor rates. By understanding these factors and following the tips provided, you can make an informed decision and potentially save money. Always hire a qualified HVAC contractor to ensure the job is done safely and correctly.