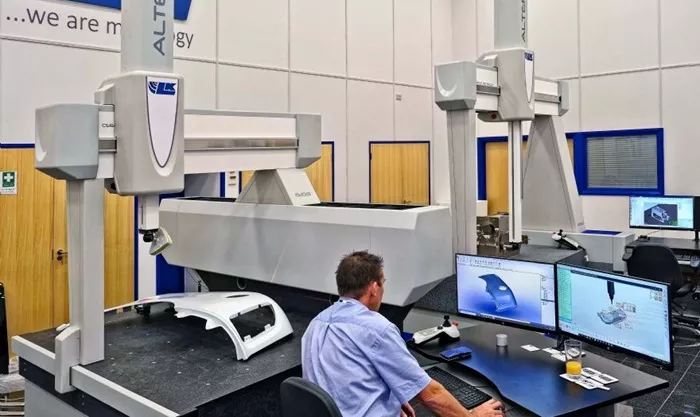

LK Metrology, a British manufacturer of coordinate measuring machines (CMMs), has introduced an innovative solution called EcoAir to make its products more environmentally friendly. The new technology significantly reduces the carbon footprint of CMMs by minimizing compressed air consumption. EcoAir is available as an optional feature for new machines produced at the company’s Castle Donington factory in Derbyshire and can also be retrofitted to existing CMMs in use across factories, quality control rooms, and metrology labs. The upgrade is compatible with any CMM brand, provided the machine is equipped with an LK NMC300 controller, which LK Metrology also offers as a retrofit.

How EcoAir Works

EcoAir is an automatic shut-off unit connected to the CMM’s air filter system. It stops the supply of compressed air to the machine’s air bearings when the CMM is idle, cutting consumption by up to 95%. This reduction translates into significant energy and cost savings for users. The system can be programmed to activate after as little as one minute of inactivity. Despite the shut-off, the CMM remains operational and ready for use. When the machine is restarted—whether in manual or CNC mode—the compressed air flow resumes automatically.

Environmental and Financial Benefits

EcoAir helps manufacturers meet stringent energy efficiency regulations and supports corporate social responsibility (CSR) initiatives. At the same time, it delivers financial benefits by lowering electricity usage. This innovation is part of LK Metrology’s ongoing efforts to make its products more sustainable.

Other Eco-Friendly Features

Over the years, LK Metrology has implemented several other measures to reduce the environmental impact of its CMMs. For example, the company has optimized the thickness of the air bearing film, which ensures smooth and precise movement of machine components. This adjustment not only reduces air consumption during operation but also increases the stiffness of the air bearings by 3.5 times compared to standard designs. The wrap-around design of these bearings enhances measurement accuracy by improving resistance to dynamic forces, particularly during tactile scanning or when using long probes.

Additionally, LK Metrology has integrated advanced motor control and intelligent power management into its CMMs. The drive motors are programmed to power down automatically when not in use, further conserving energy. The machines are also designed with lightweight materials, such as ceramic bridges and spindles, which reduce the energy required to operate them.

Conclusion

With the introduction of EcoAir and other eco-friendly innovations, LK Metrology continues to lead the way in sustainable metrology solutions. These advancements not only help manufacturers reduce their environmental impact but also deliver cost savings and improved performance, making them a win-win for businesses and the planet.