Diesel generators are everywhere, playing key roles in power supply. In cities, they keep homes running during blackouts, fridges cold, and security systems on. Offices use them to prevent data loss, and hospitals rely on them to power life – support equipment. In remote areas like construction sites, mining zones, and off – grid communities, they’re the main power source. Construction sites run heavy machinery with them, mining operations power underground equipment, and off – grid communities meet daily needs such as lighting and heating.

Understanding how much electricity, measured in kilowatt – hours (kWh), a diesel generator can produce is crucial. It helps in planning power needs accurately. For example, a small business owner needs to know this to pick the right – sized generator for outages. It also aids in cost – effectiveness assessment, as diesel fuel costs money, and knowing the power output helps calculate the cost per kWh for comparisons with other power sources. This article will explore the factors determining a diesel generator’s electricity output, including its power – generation process, influencing elements, estimation methods, and optimization strategies.

The Basics of Diesel Generator Power Generation

Power Generation Process

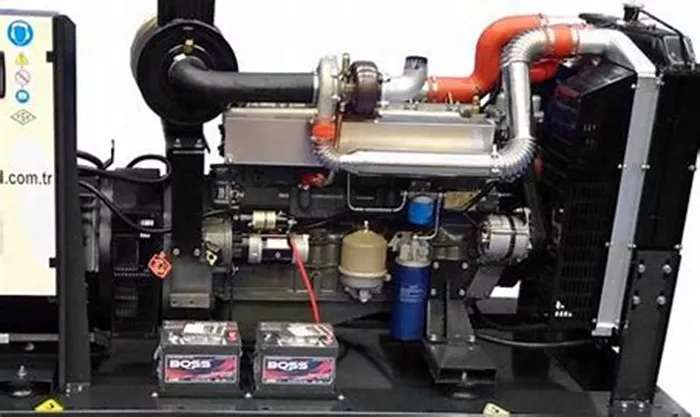

A diesel generator combines a diesel engine and an electrical generator. The diesel engine starts the process.

Air Intake and Compression: Air is drawn into the engine’s cylinders and compressed by a piston – crankshaft system. This compression boosts air density and temperature. In a typical diesel engine, air can be compressed to 15 – 25 times atmospheric pressure, with temperatures rising above 500°C.

Fuel Injection and Combustion: Diesel fuel is injected into the cylinders at high pressure. The hot compressed air makes the fuel ignite spontaneously. The combustion reaction (e.g., for a simplified diesel formula C₁₂H₂₃: 2C₁₂H₂₃ + 31O₂ → 24CO₂ + 23H₂O) releases energy in the form of expanding gases.

Mechanical Energy Transfer: The expanding gases push pistons connected to a crankshaft, converting the pistons’ reciprocating motion into the crankshaft’s rotational motion. This rotation is the mechanical energy output of the diesel engine.

Electrical Generation: The crankshaft drives the rotor of an AC generator (the most common type). As the rotor rotates, it creates a changing magnetic field. According to electromagnetic induction, this induces an electric current in the stationary stator windings, generating electrical power.

Power Output Basics

Power output is measured in kilowatts (kW), representing the rate of electrical energy production. Over time, the total energy is measured in kWh (Energy (kWh) = Power (kW) × Time (h)). For example, a 5 – kW generator running for 1 hour produces 5 kWh.

Diesel generators come in different sizes. Small portable ones, for home backup or outdoor activities, have a 1 – 10 kW output. Medium – sized generators, for small businesses or construction sites, produce 10 – 100 kW. Large industrial – grade generators, used in factories, data centers, and hospitals, can output over 1000 kW.

Factors Affecting the kWh Output of a Diesel Generator

Engine Performance

Engine Size and Power Rating: Larger engines with higher displacement can intake and burn more fuel per cycle. For instance, a 10 – liter engine can generate more power than a 3 – liter one. Engine power ratings, set by manufacturers, show the maximum power under ideal conditions. A 100 – hp engine can drive a generator to produce around 75 kW, assuming average conversion efficiency.

Combustion Efficiency: A well – designed combustion chamber, like those with high – turbulence designs, promotes better air – fuel mixing for more complete combustion. Advanced fuel injection systems, such as common – rail injection, can precisely control fuel injection based on engine conditions. Incomplete combustion due to poor mixing or incorrect fuel injection can reduce power output.

Generator Efficiency

Electrical Conversion Efficiency: Modern generators have 85% – 95% efficiency. For example, if the engine supplies 100 kW and the generator has 90% efficiency, it produces 90 kW. Magnetic circuit design, winding quality, and operating temperature affect efficiency. High – quality magnetic materials and low – resistance windings reduce losses, and cooling systems maintain optimal temperature.

Regulation and Control Systems: Voltage regulators adjust the generator’s output voltage to match the load by changing the rotor’s field current. Frequency regulators control engine speed to keep the generator’s output frequency stable, crucial for grid – connection or powering sensitive equipment. Well – functioning control systems optimize power output.

Load Conditions

Full Load vs. Partial Load: At full load, the engine works at its maximum capacity, burning more fuel. For example, a 50 – kW generator powering a 50 – kW industrial machine. At partial load, like powering a few lights at home, the engine works less, consuming less fuel. Running at very low partial loads for long can be inefficient, with increased fuel consumption per unit of power.

Load Variations and Transients: Sudden load increases, like multiple appliances turning on, can cause voltage and frequency drops. The generator’s control systems respond by increasing engine speed. However, large or frequent load changes can make the generator struggle. Transients, such as those from motor startups or inductive load switching, create voltage spikes and dips. Capacitors and flywheels can help handle these issues.

Estimating the kWh Output of a Diesel Generator

Using Manufacturer’s Specifications

Manufacturers provide the rated power, the maximum power under ideal conditions. To estimate kWh output, multiply the rated power by the runtime. For example, a 30 – kW generator running for 5 hours produces 30 kW × 5 h = 150 kWh. But actual output may vary due to load, engine, and generator efficiency. Manufacturers may also offer performance data at different load levels for more accurate estimates.

Conclusion

In summary, diesel generators are essential power sources in various settings, from urban backup power to remote – area primary supply. Their electricity production, measured in kWh, is determined by a complex interplay of factors. The power – generation process, starting from air intake and compression in the diesel engine, followed by fuel injection, combustion, mechanical energy transfer, and finally electrical generation, forms the basis of their operation.