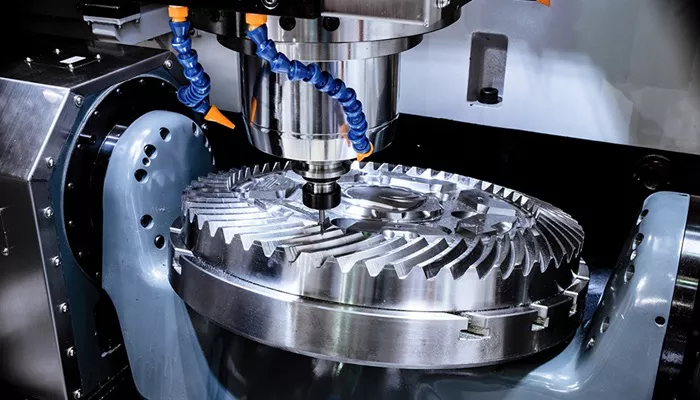

In the modern world of manufacturing, precision and efficiency are paramount. One of the technologies that have revolutionized the manufacturing industry is the 5-axis CNC (Computer Numerical Control) machine. But what exactly is a 5-axis CNC machine, and why is it so significant?

A 5-axis CNC machine allows for intricate, complex parts to be made with high accuracy and speed. It works by moving a cutting tool along five different axes. This advanced capability offers manufacturers greater flexibility and precision in producing components that would be impossible or too time-consuming to create with traditional machines.

What Are the Key Features of a 5-Axis CNC Machine?

A 5-axis CNC machine is an advanced version of traditional CNC machines, which typically operate on three axes—X, Y, and Z. These three axes correspond to movements in the horizontal, vertical, and depth directions, respectively. The 5-axis machine adds two more rotational movements, allowing the cutting tool to move freely in five directions.

This enhanced functionality significantly improves the ability to machine complex geometries, including those with multiple angled surfaces. The two additional axes allow for rotating the workpiece or the tool to access different angles during the process, which eliminates the need for multiple setups or repositioning of the material.

Additionally, the 5-axis CNC machine can perform tasks such as drilling, milling, and turning with precision. This versatility makes it an essential tool in industries such as aerospace, automotive, medical devices, and mold making.

How Does a 5-Axis CNC Machine Work?

The process of machining with a 5-axis CNC machine begins with a detailed digital model of the part to be created. This model is fed into the machine’s computer, which uses a program to control the movement of the cutting tool along the five axes. The machine then follows the instructions, precisely cutting and shaping the material.

The five axes are typically numbered as follows:

-

X-Axis: Left to right movement

-

Y-Axis: Front to back movement

-

Z-Axis: Up and down movement

-

A-Axis: Rotation around the X-Axis

-

B-Axis: Rotation around the Y-Axis

These axes can either be controlled by rotating the workpiece itself or rotating the cutting tool, depending on the machine’s configuration. The movement of these axes in unison allows for precise machining of complex, three-dimensional shapes.

Types of 5-Axis CNC Machines

There are two main types of 5-axis CNC machines: continuous 5-axis and positioning 5-axis.

-

Continuous 5-Axis: In continuous 5-axis machining, all five axes move simultaneously during the cutting process. This type of machine is ideal for manufacturing intricate components with curved or angled surfaces.

-

Positioning 5-Axis: In positioning 5-axis machines, the workpiece is moved into specific positions, and the machine rotates the tool in a series of steps. This process is typically slower than continuous machining but can still achieve high precision.

Advantages of Using a 5-Axis CNC Machine

Increased Precision and Accuracy

One of the main advantages of using a 5-axis CNC machine is its ability to achieve high levels of precision. The ability to control the tool along five axes minimizes errors and ensures that the finished product matches the digital design exactly.

Reduced Set-Up Time

Traditional CNC machines often require multiple setups to create parts with complex geometries. With a 5-axis CNC machine, the workpiece can be rotated and moved to access all necessary angles in one setup. This reduces downtime and increases productivity.

More Complex Geometries

5-axis machines are ideal for machining components with intricate designs. They can handle undercuts, curved surfaces, and other difficult shapes that would be challenging or impossible with simpler machines.

Improved Surface Finish

Because of the continuous motion of the axes, the tool can be kept at an optimal angle during the entire cutting process, resulting in a smoother surface finish. This is especially beneficial for industries like aerospace and medical device manufacturing, where surface quality is crucial.

Applications of 5-Axis CNC Machines

Aerospace Industry

The aerospace industry demands parts with high precision, complex shapes, and tight tolerances. A 5-axis CNC machine is perfect for manufacturing components like turbine blades, aircraft wing structures, and engine components. These parts require intricate designs and high-quality finishes, making the 5-axis CNC machine an essential tool.

Automotive Industry

In the automotive sector, 5-axis CNC machines are used to produce engine blocks, suspension parts, and molds for car bodies. The ability to machine multiple surfaces in a single setup is critical for improving production efficiency and reducing costs.

Medical Devices

The medical device industry also benefits from the precision of 5-axis machining. It allows for the production of parts such as surgical tools, implants, and prosthetics, all of which require exacting tolerances and smooth finishes.

Mold Making

Mold making for industries such as injection molding and die casting can be significantly enhanced with 5-axis CNC machines. These machines can quickly and accurately shape complex molds with multiple angled surfaces, reducing production time.

Challenges of Using a 5-Axis CNC Machine

Despite their advantages, 5-axis CNC machines come with some challenges.

High Cost

5-axis machines are more expensive than traditional CNC machines due to their advanced technology and additional axes. This makes them a significant investment for companies, which may deter smaller operations from adopting this technology.

Complexity in Programming

Programming a 5-axis CNC machine requires more expertise and experience than programming simpler machines. Specialized software and skilled operators are necessary to maximize the potential of the machine and avoid costly errors.

Maintenance and Repair

5-axis CNC machines are more complex and have more moving parts than traditional machines. As such, they require more frequent maintenance and care to ensure smooth operation. In addition, repairs can be costly and require specialized knowledge.

Conclusion

The 5-axis CNC machine is an invaluable tool in modern manufacturing, offering precision, flexibility, and efficiency in producing complex components. While they come with a high price tag and require skilled operators, the benefits they provide in terms of reduced setup times, superior surface finishes, and the ability to machine intricate geometries make them an essential piece of equipment in industries like aerospace, automotive, and medical device manufacturing. As the technology continues to evolve, it is likely that the role of 5-axis CNC machines will only grow in importance, allowing manufacturers to meet the demands of increasingly complex and high-quality products.