In modern society, diesel generators have emerged as a linchpin of reliable power supply. They are deployed in a wide array of situations, from restoring power during outages in bustling residential neighborhoods to maintaining continuous operations in large – scale industrial plants. Given their significance, a fundamental question frequently surfaces: do diesel generators churn out alternating current (AC) or direct current (DC)? This article delves into the structure, working principles, and real – world applications of diesel generators, aiming to shed light on this very question.

Anatomy and Fundamental Working Mechanisms

The Structure of Diesel Generators

A diesel generator is essentially a combination of a diesel engine and an electrical generator. The diesel engine serves as the prime mover, converting the chemical energy of diesel fuel into mechanical energy through a series of combustion processes. This mechanical energy then drives the generator, which converts it into electrical energy.

The diesel engine typically consists of components such as cylinders, pistons, valves, and a crankshaft. During operation, air is drawn into the cylinders, compressed, and then mixed with atomized diesel fuel. The resulting combustion generates high – pressure gases that push the pistons, driving the crankshaft to rotate.

Principles of Electrical Generation

There are two main types of generators used in diesel generator systems: AC generators and DC generators, each operating on distinct principles.

AC Generators

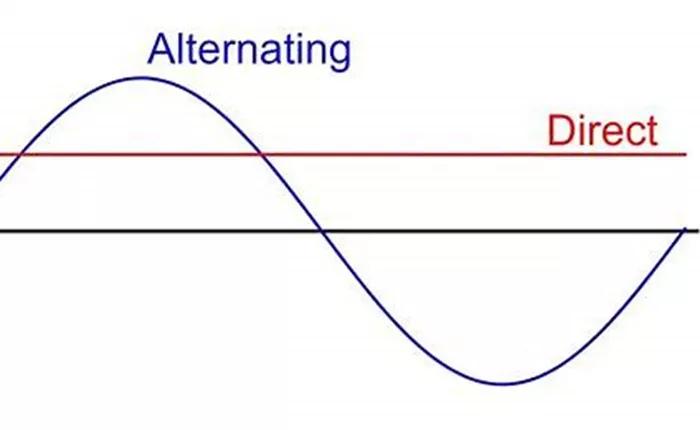

AC generators, also known as alternators, are the more common type in diesel generator setups. An AC generator typically has a rotating magnetic field (rotor) and a stationary set of coils (stator). When the diesel engine drives the rotor to spin, it creates a rotating magnetic field. As this magnetic field passes through the stator coils, it induces an alternating current in the coils according to Faraday’s law of electromagnetic induction. The frequency of the generated AC power depends on the rotational speed of the rotor and the number of magnetic poles. In most cases, diesel – powered AC generators are designed to produce electricity at a standard frequency, such as 50 or 60 hertz, which is suitable for use in homes, industries, and the electrical grid.

DC Generators

DC generators operate on a similar principle of electromagnetic induction but with a key difference. They use a commutator, a mechanical device that reverses the connection of the generator’s windings at the appropriate time to ensure that the output current flows in a single direction. A DC generator consists of a stator with a magnetic field and a rotating armature with coils. As the armature rotates in the magnetic field, an alternating voltage is induced in the coils. The commutator then converts this alternating voltage into a direct current. However, DC generators are less commonly used in diesel generator applications compared to AC generators due to their more complex design and higher maintenance requirements.

Why AC Generators Prevail in Most Applications

Compatibility with Electrical Grids & Equipment

One of the primary reasons AC generators are more prevalent in diesel generator setups is their compatibility with the electrical grid and most electrical equipment. The electrical grid operates on AC power, and most household and industrial appliances are designed to run on AC. By generating AC power, diesel generators can easily be connected to the grid or used to power a wide range of electrical devices without the need for additional conversion equipment. This simplifies the installation and operation of diesel generator systems.

Easier Voltage Regulation

AC generators also offer more straightforward voltage regulation. Voltage regulators can be easily incorporated into AC generator systems to maintain a stable output voltage, even under varying load conditions. This is crucial for ensuring the proper functioning of sensitive electrical equipment, such as computers, medical devices, and industrial machinery. In contrast, voltage regulation in DC generators is more complex and often requires additional components.

Lower Cost & Maintenance

AC generators generally have a lower cost and require less maintenance compared to DC generators. Their simpler design, without the need for a commutator, reduces the number of moving parts and the likelihood of mechanical failure. Additionally, the availability of off – the – shelf AC components makes repairs and replacements more convenient and cost – effective.

Scenarios Where DC Generators Find Use

Specialized Industrial Applications

Although AC generators are dominant, DC generators still have their place in certain specialized industrial applications. For example, in some industrial processes that require a direct current, such as electroplating, electrolysis, or battery charging, DC generators can be used to provide the necessary power. In these cases, the use of a DC generator eliminates the need for additional rectification equipment to convert AC power to DC.

Remote & Off – Grid Systems

DC generators may also be used in remote or off – grid systems where the primary goal is to charge batteries. In areas where access to the electrical grid is limited or unavailable, diesel – powered DC generators can be used to charge batteries, which can then be used to power DC – operated devices or converted to AC using an inverter. This setup is commonly found in remote communication stations, solar – diesel hybrid systems, and some off – grid residential applications.

Converting Between AC & DC

AC to DC Conversion

In cases where DC power is required from an AC – generating diesel generator, rectifiers are used to convert AC power to DC. A rectifier is an electrical device that allows current to flow in only one direction, effectively converting the alternating current into a direct current. There are different types of rectifiers, including half – wave rectifiers, full – wave rectifiers, and bridge rectifiers, each with its own characteristics and applications.

DC to AC Conversion

Conversely, if AC power is needed from a DC – generating diesel generator, inverters are used. An inverter is a device that converts direct current into alternating current. Inverters can produce AC power with different frequencies and waveforms, depending on the specific requirements of the application. Inverters are commonly used in off – grid systems, where batteries charged by DC generators are used to power AC – operated devices.

Conclusion

In conclusion, most diesel generators produce AC power due to its compatibility with the electrical grid, ease of voltage regulation, and lower cost and maintenance requirements. However, DC generators still have their applications in specialized industrial processes and remote off – grid systems. Understanding the differences between AC and DC generators and their respective applications is essential for choosing the right diesel generator system for a particular power – generation need. Whether it’s powering a home during a power outage, providing backup power for an industrial facility, or supporting a remote off – grid community, the choice between an AC or DC diesel generator can significantly impact the efficiency, reliability, and cost – effectiveness of the power – generation system.