Swiss Steel Group has launched UGIMA-X, the third generation of high-machinability stainless steels. This new range promises significant improvements in machining efficiency, tool life, and process consistency. UGIMA-X is the result of over 30 years of research and close collaboration with industrial partners.

The UGIMA-X series includes three distinct grades: UGIMA-X 4021, UGIMA-X 4028, and UGIMA-X 4460. UGIMA-X 4021 is a martensitic stainless steel ideal for demanding mechanical or food and beverage applications that require high strength. UGIMA-X 4028, another martensitic stainless steel, offers enhanced mechanical resistance while also being suitable for food and beverage components that need high precision. UGIMA-X 4460 is a duplex stainless steel that combines excellent mechanical properties with outstanding corrosion resistance, all while being easy to machine.

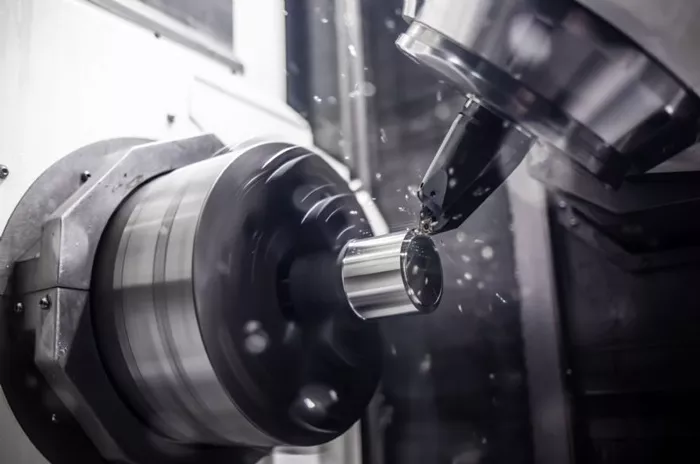

Swiss Steel reports that these new materials provide a 20% increase in productivity, a 25-50% extension in tool life, improved chip breakability, and exceptional consistency across production batches. The company explains that UGIMA-X’s development involved precise modifications to non-metallic inclusions, particularly through the introduction of oxides during the melting process. These improvements reduce tool wear and enhance chip formation, ensuring consistent machining properties across different heats.

A key advantage of UGIMA-X is the significant reduction in quality variations, which have traditionally been a challenge in stainless steel machining. Extensive studies in both research labs and real-world industrial trials confirmed the consistent performance of UGIMA-X, which was developed over three years and involved the production of 2,000 tonnes of material and 3,000 hours of testing.

In addition to its technological advancements, UGIMA-X grades are aligned with sustainable production practices. The materials are available in a ‘Climate+’ version, produced using electricity exclusively from renewable sources like wind, solar, and hydropower.