Diesel generators are essential power sources in various scenarios, from providing backup power during outages to powering remote construction sites or industrial operations. But have you ever wondered what makes these generators tick? Understanding the main components of a diesel generator can not only give you insights into how it functions but also help in its maintenance and troubleshooting. In this article, we’ll explore the nine crucial components that form the heart and soul of a diesel generator.

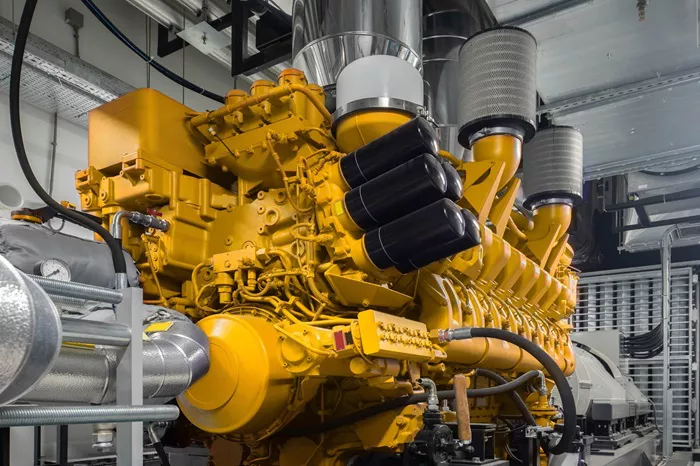

The Powerhouse: Diesel Engine

The diesel engine is the prime mover of a diesel generator. It’s responsible for converting the chemical energy stored in diesel fuel into mechanical energy. This mechanical energy is then used to drive the generator and produce electricity. A diesel engine in a generator works on the same principle as those in trucks, buses, or other heavy – duty vehicles. It consists of a cylinder block, pistons, a crankshaft, and a combustion chamber. The combustion of diesel fuel in the combustion chamber forces the pistons to move up and down, which in turn rotates the crankshaft. The size and capacity of the diesel engine determine the power output of the generator. Larger engines can produce more mechanical energy, enabling the generator to supply higher electrical power.

The Electricity Producer: Alternator (AC Generator)

The alternator, also known as an AC generator, is where the magic of electricity generation happens. It takes the mechanical energy from the diesel engine and converts it into electrical energy in the form of alternating current (AC). Inside the alternator, there are two main parts: the rotor and the stator. The rotor is a rotating component, often with an electromagnet or permanent magnets. When the diesel engine rotates the rotor, it creates a magnetic field. The stator, on the other hand, is a stationary part made up of coils of wire. As the magnetic field from the rotor rotates around the stator, it induces an electric current in the stator coils according to Faraday’s law of electromagnetic induction. This induced current is the electrical power that the generator supplies to the connected loads.

The Fuel Supplier: Fuel System

A reliable fuel system is crucial for a diesel generator to keep running. The fuel system typically includes a fuel tank, fuel lines, a fuel pump, and a fuel filter. The fuel tank stores the diesel fuel, and its size determines how long the generator can operate without refueling. Fuel lines connect the tank to the engine, allowing the fuel to flow. The fuel pump is responsible for pushing the fuel from the tank to the engine at the required pressure. Before reaching the engine, the fuel passes through a fuel filter. The filter’s job is to remove any impurities, such as dirt or water, from the fuel. This ensures that clean fuel enters the engine, preventing damage to the engine’s sensitive components like the injectors. A clogged fuel filter or a malfunctioning fuel pump can cause the generator to run poorly or even stop working.

The Voltage Guardian: Voltage Regulator

The voltage regulator is an important component that ensures the generator outputs a stable and consistent voltage. In an AC generator, the voltage can fluctuate depending on various factors, such as the load connected to the generator and the speed of the diesel engine. The voltage regulator constantly monitors the output voltage of the generator. If the voltage starts to deviate from the desired set – point, the regulator takes corrective action. It does this by adjusting the field current in the alternator’s rotor. By changing the field current, the strength of the magnetic field in the rotor is adjusted, which in turn affects the voltage induced in the stator coils. This process keeps the output voltage within the acceptable range, protecting the electrical devices connected to the generator from over – voltage or under – voltage conditions.

The Heat Busters: Cooling and Exhaust Systems

Diesel engines generate a significant amount of heat during operation. The cooling system is designed to dissipate this heat and keep the engine and other components at a safe operating temperature. A typical cooling system consists of a radiator, a water pump, a thermostat, and coolant. The water pump circulates the coolant (a mixture of water and antifreeze) through the engine block and cylinder head, absorbing the heat generated by the engine. The hot coolant then flows to the radiator, where it releases the heat to the surrounding air. The thermostat controls the flow of coolant, ensuring that the engine reaches and maintains its optimal operating temperature.

At the same time, the exhaust system is responsible for removing the combustion gases produced by the diesel engine. These gases, which include carbon dioxide, nitrogen oxides, and particulate matter, are harmful to the environment and human health. The exhaust system starts from the engine’s exhaust manifold and includes components like mufflers and catalytic converters. The muffler reduces the noise of the exhaust gases, while the catalytic converter helps to reduce the harmful emissions by converting them into less harmful substances.

The Lubrication Protector: Lubrication System

The lubrication system is like the lifeblood of the diesel engine. It ensures that all the moving parts of the engine, such as the pistons, crankshaft, and bearings, are properly lubricated. This reduces friction between the parts, preventing excessive wear and tear and extending the engine’s lifespan. The lubrication system typically consists of an oil pan, an oil pump, oil filters, and oil passages within the engine block. The oil pan stores the engine oil. The oil pump sucks the oil from the pan and pumps it through the oil filters to remove any contaminants. The clean oil then flows through the oil passages to reach all the moving parts of the engine. Without proper lubrication, the engine parts would quickly overheat and seize up, causing major damage to the engine.

The Battery Booster: Battery Charger

Diesel generators often require a battery to start the engine. The battery charger is responsible for keeping the battery charged. It takes a small amount of the electrical power generated by the generator and uses it to charge the battery. There are different types of battery chargers, such as float chargers and smart chargers. A float charger maintains a constant voltage to keep the battery charged without overcharging it. Smart chargers, on the other hand, can adjust the charging voltage and current based on the battery’s state of charge. A properly charged battery is essential for the reliable starting of the diesel generator, especially during emergencies when immediate power is needed.

The Control Center: Control Panel

The control panel is the interface between the operator and the diesel generator. It allows the operator to monitor the generator’s performance and control its operation. The control panel typically includes indicators for various parameters such as engine speed (RPM), voltage, current, oil pressure, and coolant temperature. There are also switches for starting and stopping the generator, as well as for selecting the operating mode (manual or automatic). Some advanced control panels may also have features like fault diagnosis, where they can detect and display any problems with the generator, such as low oil pressure or high temperature. This helps the operator to quickly identify and address any issues, ensuring the smooth running of the generator.

The Foundation: Main Frame or Skid

The main frame, also known as a skid, provides a stable base for all the components of the diesel generator. It holds the diesel engine, alternator, fuel tank, and other components in place. The frame is designed to withstand the vibrations and forces generated by the running engine and to protect the components from damage. In addition, the frame may also be used for mounting the generator on a trailer for easy transportation in mobile applications. It is often made of sturdy materials like steel to ensure durability and strength.

Conclusion

In conclusion, a diesel generator is a complex yet fascinating piece of equipment, and its nine main components work in harmony to provide reliable power. From the diesel engine that kicks off the energy conversion process to the control panel that allows for seamless operation, each part plays a vital role. The fuel system keeps the engine running, the alternator generates electricity, and the voltage regulator ensures a stable power supply. Meanwhile, the cooling and exhaust systems manage heat and emissions, the lubrication system protects the engine, the battery charger maintains the starting power, and the main frame provides structural support. Understanding these components not only gives us a better appreciation of how diesel generators work but also equips us with the knowledge to maintain and troubleshoot them effectively. Whether you’re using a diesel generator for backup power at home, on a job site, or in an industrial setting, this understanding can help you make the most of your generator and keep it running smoothly for years to come.