The air conditioning (AC) compressor clutch is a critical component in automotive and HVAC systems. It engages and disengages the compressor from the engine or motor, allowing the AC system to operate only when cooling is needed. Understanding its location, function, and operation is essential for technicians, engineers, and automotive enthusiasts.

Definition & Purpose of the AC Compressor Clutch

Engagement: Connects the compressor pulley to the drive shaft when the AC is activated.

Disengagement: Stops the compressor when cooling is not required, reducing engine load and improving fuel efficiency.

Protection: Prevents compressor damage by disengaging during system malfunctions (e.g., low refrigerant).

Without a functioning clutch, the compressor would run continuously, leading to excessive wear and energy consumption.

Location in the AC System

Front of the Compressor: The clutch is attached to the compressor’s input shaft.

Belt-Driven System: The clutch pulley is connected to the engine’s accessory belt (V-belt or serpentine belt).

Proximity to Other Components: It is often near the tensioner, idler pulleys, and other belt-driven accessories.

In most vehicles, the compressor is mounted at the engine’s front or side, making the clutch accessible for inspection and servicing.

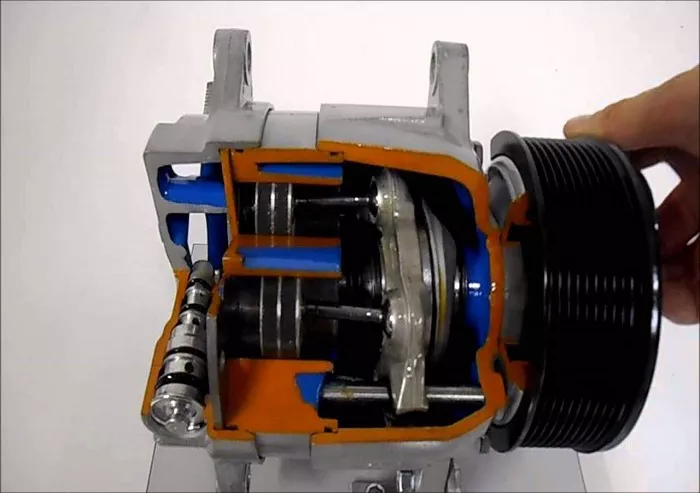

Components & Design

Clutch Pulley (Drive Plate)

- Rotates continuously with the engine belt.

- Contains a bearing to allow free rotation when disengaged.

- Made of durable steel or aluminum to withstand high RPMs.

Electromagnetic Coil (Clutch Coil)

- Mounted behind the pulley.

- When energized, it creates a magnetic field to pull the clutch plate.

- Operates on 12V (automotive) or 24V (commercial vehicles).

Clutch Plate (Armature Plate)

- Attached to the compressor shaft.

- Engages with the pulley when the coil is activated.

- Contains friction material for smooth engagement.

Common Failure Symptoms

AC Blowing Warm Air

- The clutch fails to engage, preventing compressor operation.

Unusual Noises

- Worn bearings or misaligned clutch components.

Visible Damage

- Overheating or excessive wear due to prolonged use.

Belt Slippage or Burning Smell

- Clutch not fully disengaging, causing belt friction.

Replacement & Maintenance

Removal

- Disconnect the battery.

- Remove the serpentine belt.

- Unbolt the clutch assembly using a puller tool.

Installation

- Install a new clutch with proper shimming for correct air gap.

- Reconnect electrical wiring and belt.

Maintenance Tips

- Keep the clutch clean from oil and debris.

- Regularly inspect belt tension and alignment.

- Ensure refrigerant levels are correct to avoid unnecessary cycling.

Industry Standards & Innovations

Variable Displacement Compressors: Reduce clutch cycling for smoother operation.

Smart Clutch Systems: Use sensors for adaptive engagement.

Lightweight Materials: Improve efficiency and reduce inertia.

Conclusion

The AC compressor clutch is a vital component that ensures efficient and controlled operation of the air conditioning system. Understanding its location, function, and failure modes helps technicians diagnose and repair issues effectively. With advancements in automotive technology, clutch designs continue to evolve, improving reliability and performance. By following proper maintenance and diagnostic procedures, professionals can extend the lifespan of the AC compressor clutch, ensuring optimal cooling performance in vehicles and HVAC systems.