In a recent webinar hosted by the Engine Technology Forum (ETF), Jim Nebergall, General Manager of Cummins’ hydrogen engine division, provided an in-depth look at the future of hydrogen internal combustion (IC) engines and their role in vehicle decarbonization. Nebergall emphasized that achieving significant reductions in carbon emissions will necessitate a multifaceted approach, integrating advanced combustion engines, battery-electric systems, and fuel cells.

Cummins’ strategy, known as HELM—an acronym for Higher Efficiency, Lower Emissions, Multiple Fuels—underpins this vision. Jane Beaman, who leads Cummins’ on-highway business, explained in a company video that the HELM approach empowers customers to choose the fuel type that best aligns with their specific needs and objectives. “This strategy provides our customers with the flexibility to select the most suitable fuel for their operations,” Beaman said.

Engines developed under the HELM program are designed to accommodate various fuel types, including hydrogen, with minimal modifications required. “Engines can be ordered from the factory as diesel, natural gas, or hydrogen versions,” Nebergall told Power Progress. “This investment strategy is aimed at ensuring flexibility and offering a broad range of market options, reflecting our belief in the necessity of diverse solutions for decarbonization.”

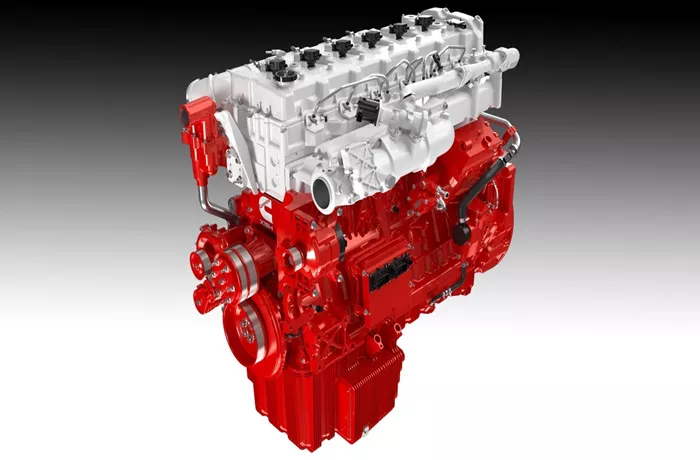

Currently, two engines from the HELM program—a 6.7-liter and a 15-liter model—are progressing towards readiness for hydrogen fuel. “We are actively testing these engines across multiple continents,” Nebergall noted. “They are undergoing rigorous evaluation in test cells worldwide.”

Leveraging Spark-Ignited Engine Experience

Cummins’ experience with spark-ignited engines, particularly those running on natural gas, is instrumental in making hydrogen engines commercially viable. “Our extensive background with natural gas spark-ignited engines provides a strong foundation,” Nebergall said. “Although hydrogen fuel presents different characteristics, the design similarities are significant.”

Nebergall also highlighted that hydrogen engines will feature lean-burn technology, which necessitates aftertreatment systems similar to those used in diesel engines. “The aftertreatment for hydrogen engines will resemble that of diesel engines, utilizing selective catalytic reduction (SCR) for NOx control,” he explained. This differs from natural gas engines, which use a three-way catalyst due to their stoichiometric nature.

Diesel-Like Performance

In the ETF webinar, Nebergall pointed out that hydrogen IC technology closely mirrors diesel engines in terms of performance. “Hydrogen engines offer comparable power and torque, and they can operate effectively in existing environments and equipment,” he said.

A key factor contributing to this performance is the use of direct injection technology. “Hydrogen engines feature a fuel injector per cylinder, unlike port fuel-injected engines where fuel is introduced into the intake manifold,” Nebergall added. This technology enables hydrogen engines to achieve power and torque levels comparable to modern diesel engines, positioning them as a viable option in the quest for cleaner internal combustion solutions.

Related topics:

- Rimac Energy’s SineStack Set for UK Deployment

- HD Hyundai and Develon Open State-of-the-Art Customization Plant in Georgia

- Volvo Trucks Unveils Electric FH Model with 600-Kilometer Range for Long-Distance Hauling