Direct Current (DC) generators are electromechanical devices that convert mechanical energy into electrical energy in the form of direct current. These machines are fundamental in various applications, from small-scale power generation to industrial uses. Understanding how a DC generator operates requires a grasp of its key components, the principles of electromagnetic induction, and the process of converting alternating current (AC) into direct current (DC). This article provides a detailed explanation of the operation of a DC generator.

Key Components of a DC Generator

Armature: The armature is the rotating part of the generator, consisting of coils of wire wound around a core. It is responsible for generating the electrical output as it rotates within a magnetic field.

Field Magnets: These are the stationary magnets that produce a magnetic field. The armature rotates within this magnetic field, inducing an electromotive force (EMF) in the armature windings.

Commutator: The commutator is a cylindrical structure mounted on the rotor shaft, consisting of multiple copper segments insulated from each other. It plays a crucial role in converting the alternating current generated in the armature into direct current.

Brushes: The brushes are stationary components made of carbon or graphite. They maintain contact with the commutator segments and conduct the current to the external circuit.

Shaft: The shaft is the mechanical component that connects the armature to an external source of mechanical energy, such as a turbine or an engine. The rotation of the shaft drives the armature.

Principles of Operation

The operation of a DC generator is based on the principle of electromagnetic induction, discovered by Michael Faraday. According to this principle, a change in magnetic flux through a coil of wire induces an electromotive force (EMF) in the coil. The magnitude of the induced EMF is proportional to the rate of change of the magnetic flux.

Step-by-Step Operation of a DC Generator

Mechanical Energy Input: The process begins with the application of mechanical energy to the generator’s shaft. This mechanical energy can come from various sources, such as a steam turbine, internal combustion engine, or even a hand crank.

Rotation of the Armature: As the shaft rotates, it drives the armature, causing it to spin within the magnetic field produced by the field magnets.

Generation of Alternating Current: The rotation of the armature within the magnetic field induces an EMF in the armature windings. According to Faraday’s Law of Electromagnetic Induction, the changing magnetic flux through the coils generates an alternating current (AC) in the windings.

Role of the Commutator: The commutator is essential for converting the alternating current generated in the armature into direct current. The commutator consists of multiple segments, each connected to the ends of the armature windings. As the armature rotates, the commutator segments alternately make contact with the stationary brushes.

Rectification Process: When the current in the armature windings reverses direction, the commutator ensures that the connection to the external circuit is also reversed. This switching action rectifies the alternating current into direct current, ensuring that the current flowing through the external circuit remains unidirectional.

Output of Direct Current: The brushes maintain continuous contact with the commutator segments, conducting the rectified current to the external circuit. The result is a steady flow of direct current, which can be used to power various electrical devices and systems.

Applications of DC Generators

Industrial Machinery: DC generators are used in industries to power heavy machinery and equipment that require a stable and reliable source of direct current.

Battery Charging: DC generators are commonly used to charge batteries in vehicles, renewable energy systems, and backup power supplies.

Electroplating: The consistent and controllable current provided by DC generators makes them ideal for electroplating processes, where a metal coating is applied to a surface using electrical current.

Traction Systems: DC generators are used in electric trains and trams to provide the necessary power for traction motors.

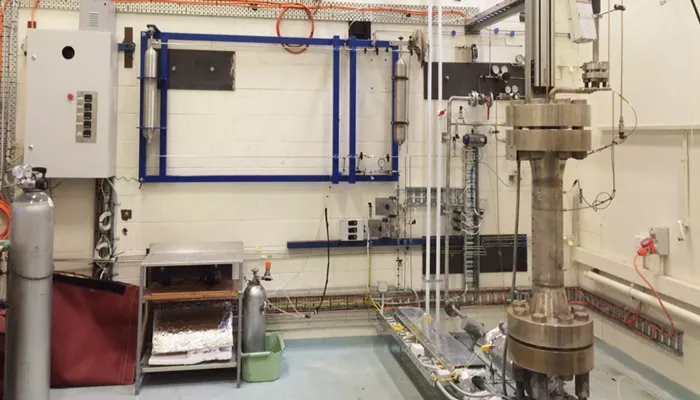

Laboratory and Testing: DC generators are used in laboratories and testing environments to provide a precise and adjustable source of direct current for experiments and equipment testing.

Conclusion

The operation of a DC generator is a fascinating interplay of mechanical and electrical principles. By converting mechanical energy into electrical energy through electromagnetic induction and rectifying the resulting alternating current into direct current, DC generators provide a reliable and versatile power source for a wide range of applications. Understanding the key components and the step-by-step process of how a DC generator operates is essential for appreciating its role in modern technology and industry.

From industrial machinery and battery charging to electroplating and traction systems, DC generators continue to be an integral part of our electrical infrastructure. Their ability to produce a steady and controllable direct current makes them indispensable in various fields, ensuring the efficient and effective operation of countless devices and systems.