Manufacturers are under increasing pressure to improve production efficiency and adapt to varying customer demands. One solution gaining traction is the use of automatic gripper changes in CNC machines. This technology allows machines to switch tasks effortlessly, removing the need for manual adjustments. Hakan Aydogdu, CEO of Tezmaksan Robot Technologies, discusses how these automated systems can streamline manufacturing operations and boost productivity.

In traditional CNC setups, switching between different workpieces requires manual intervention. This process can be time-consuming and prone to errors, causing delays and bottlenecks in production. These bottlenecks can disrupt workflows and lead to higher costs, especially in industries with custom orders or fluctuating production schedules.

Automatic gripper changes address these issues by enabling CNC machines to quickly and easily shift between tasks. This automation ensures a smooth, continuous production flow, allowing manufacturers to meet tight deadlines and operate more efficiently.

In industries with high-mix, low-volume production, where customization and small batch sizes are common, flexibility is essential to stay competitive. Automatic gripper changes provide CNC machines with the ability to handle various workpieces without interrupting the process, helping manufacturers fulfill diverse customer orders without sacrificing output.

Precision and repeatability are crucial in sectors like aerospace and automotive, where even minor errors can have serious consequences. While manual adjustments can introduce variability, automatic gripper changes maintain consistency, leading to better quality products and fewer defects.

The adoption of automation technologies like automatic gripper changes supports the goals of Industry 5.0, which emphasizes combining digital technology with human-centered production. By implementing these solutions, manufacturers can boost efficiency, accuracy, and flexibility while providing workers with more user-friendly tools.

For small and medium-sized enterprises (SMEs), retrofitting existing CNC machines with automation technology offers a cost-effective way to modernize without the need for expensive new equipment. Hardware-agnostic solutions allow manufacturers to upgrade their machines, extending their life span and reducing the need for costly replacements.

Modern automation systems are designed to integrate easily into existing setups, featuring plug-and-play options that make it simple for SMEs to gradually enhance their production capabilities. This approach helps businesses meet the demands of a more digitally-driven manufacturing landscape.

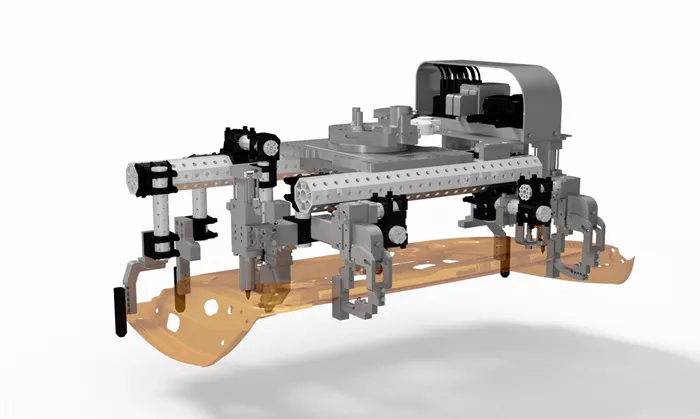

Tezmaksan’s CubeBOX CNC automation system integrates automatic gripper changes into workflows, enabling smooth transitions between tasks. This technology is especially useful for manufacturers who must balance diverse production needs with high throughput and tight delivery schedules.