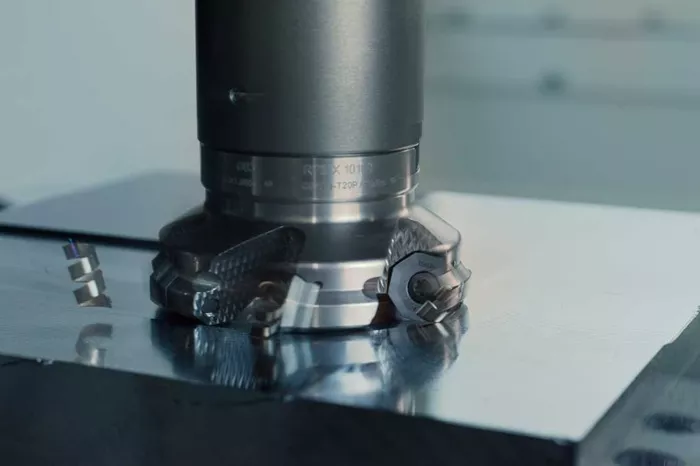

The latest version of the Seco Octomill 06 Face Milling Cutter brings major improvements in usability, flexibility, and stability. Built for precision and reliability, this cutter includes a self-centering insert system for quick, error-free setup. It also features a multi-insert pocket design that works with different insert types, making it suitable for a wide range of machining tasks.

The Octomill 06’s self-centering inserts ensure fast and secure positioning with high repeatability. A long insert screw allows users to index inserts easily without removing the screw from the cutter body. The cutter’s innovative design separates cutting edges from support surfaces, combining the durability of double-sided inserts with the simplicity of a single-sided design.

“By isolating worn parts of the insert from support surfaces, we avoid performance problems and protect unused edges,” explained Tobias Jakobi, Seco Product Manager. “The self-centering feature also prevents incorrect insert placement, reducing instability, edge damage, and costly downtime.”

The Octomill 06 has a right-handed design, a straight cutting edge, and a high helix angle of +16°. These features reduce radial and axial forces, ensuring smoother entry and exit during cutting. It also minimizes back cutting effects and evenly distributes wear along the cutting edge. This makes the cutter ideal for unstable setups or thin-walled parts, while maintaining high production quality.

The cutter’s multi-insert pocket design adds versatility, allowing it to handle face milling, round, and moderate high-feed inserts. This flexibility means one cutter body can perform multiple machining tasks, reducing the need for additional tools and boosting productivity.

The Octomill 06 is highly effective for face milling, ramping, helical interpolation, and profiling, making it a versatile choice for various milling applications. Its adaptability ensures consistent performance across different tasks, improving efficiency and extending tool life. Additionally, a wide range of insert grades and geometries are available to optimize performance across materials, including those in the P, M, K, N, S, and H Seco Materials Groups.

With its improved stability, ease of use, and versatility, the Octomill 06 is a top choice for manufacturers looking for precision, efficiency, and reduced downtime in face milling operations.