At TIMTOS 2025, held from March 3-8 in Taipei, Taiwan, the event’s theme, “Integrate to Innovate,” focused on three key areas: AI & Robotics, Smart Manufacturing, and Green Sustainability. The exhibition, which hosted 1,000 exhibitors and attracted nearly 50,000 visitors, underscored the growing collaboration in the machine tool industry.

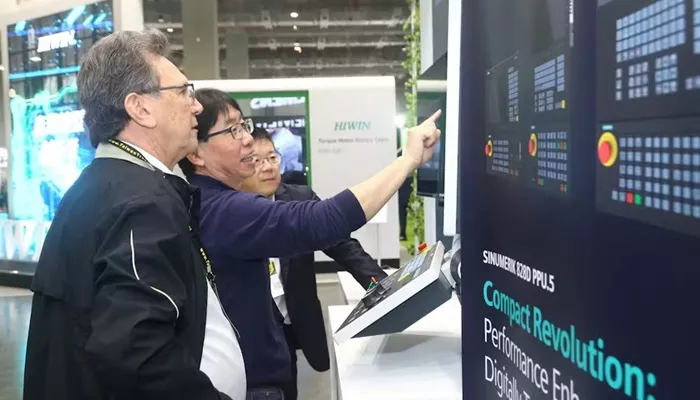

Siemens, a global leader in technology, showcased its innovative solutions in smart manufacturing and machine tools at the event. The company highlighted the role of integrated AI, automation, and robotics in shaping the future of manufacturing. Siemens, which has been a trusted partner to medium-sized companies in Taiwan for decades, emphasizes the importance of these technologies for next-generation production.

Supporting Taiwan’s Machine Tool Industry

Ben Tan, Siemens’ head of Machine Tool, shared with Machine Design that the company works with over 100 machine builders in Taiwan. While this broad collaboration offers opportunities, it also presents challenges, as Siemens faces competition from other regions and countries.

“At TIMTOS, our goal is not just to support small machinery businesses, but to accelerate their transformation,” Tan said. “We aim to innovate for both the machine builder and the CNC job shops that rely on them.”

Taiwan is home to the third-largest machine tool industry globally, behind only the semiconductor and panel industries. According to the International Trade Administration (ITA), Taiwan produced $48 billion worth of machinery and exported $34 billion. It ranks among the top ten machine tool producers, alongside countries like China, Germany, Japan, and the United States.

The Role of Digital Twins in Modern Manufacturing

Siemens is helping machine builders improve efficiency by using digital twins—virtual models of physical assets. These digital models enable engineers to simulate and test machines before they are physically built, saving both time and money.

Tan explained that digital twins allow machine builders to perform simulations and identify potential problems early in the design process. This helps reduce mistakes during production and shortens the time it takes to bring machines to market. “By working with digital models, customers can prepare and test their designs before moving to the physical world,” Tan said.

Digital twins also enhance design departments by allowing engineers to verify machine designs through simulations before physical assembly. “Using digital twins helps ensure the design meets customer requirements and makes the process faster and more reliable,” Tan added.

AI and Adaptive Control Monitoring for Enhanced Productivity

At the Siemens booth, attendees learned about the integration of advanced technologies like Adaptive Control Monitoring (ACM), which optimizes manufacturing processes using machine learning.

ACM software helps machines “learn” from their first cutting of a workpiece. After analyzing the initial cut, the controller adjusts the process for optimal cutting conditions, resulting in a 15% to 20% reduction in machining time. This improves productivity, reduces energy consumption, and enhances efficiency on the CNC shop floor.

Christine Herbst-Kubitz, General Manager of Siemens Taiwan Digital Industries, explained the various ways ACM can be applied to metal-cutting operations like milling, turning, and grinding. She demonstrated how ACM can optimize a machine’s feed rate in real-time, adjusting the speed for better performance or slowing down when needed due to material hardness or tool condition.

ACM, driven by machine learning, can adapt spindle load and speed to increase productivity. It can also adjust cutting speeds based on conditions, ensuring that the machine operates efficiently while minimizing energy use.

Looking to the Future of Manufacturing

Siemens’ contributions to TIMTOS 2025 emphasize the role of AI, robotics, and digital technology in transforming manufacturing. As digital twins and AI integration continue to evolve, they promise to further streamline design processes, enhance productivity, and support sustainable practices within the global machine tool industry.