Welding is a crucial process in the machinery industry, with different welding techniques suited for varying tasks. Among these techniques, MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding stand out as the most popular. While both methods use an electric arc to join metals, the way they achieve this and the results they produce differ significantly.

In this article, we will compare MIG and TIG welding in terms of efficiency, quality, versatility, cost, and other important factors, helping you make an informed decision on which method is best suited for your project.

Understanding MIG and TIG Welding

What is MIG Welding?

MIG welding is a type of welding process where a continuous solid wire electrode is fed through a welding gun and melted to join two pieces of metal. The process uses an inert gas like argon or a gas mixture to shield the weld from contamination in the air. MIG welding is known for its speed, ease of use, and efficiency, making it suitable for both beginners and experienced welders.

MIG welding is commonly used in industrial settings for jobs that require fast production, like automotive manufacturing and construction. It is also used in applications where the quality of the weld is not as critical, but speed and cost-effectiveness are essential.

What is TIG Welding?

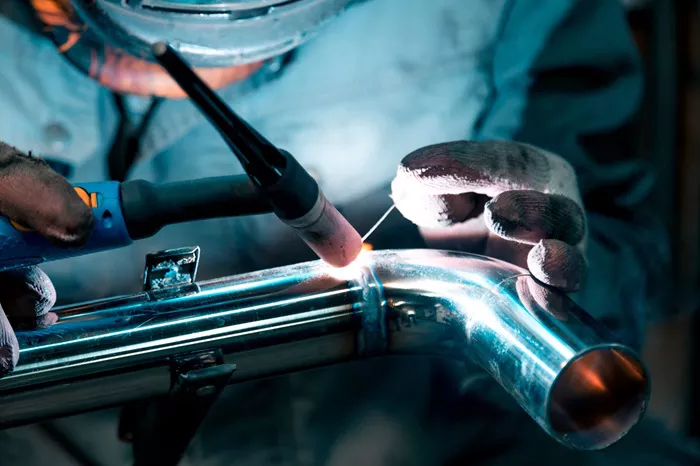

TIG welding is a more precise method that uses a non-consumable tungsten electrode to create the arc. The process requires the welder to manually feed filler material into the weld pool, ensuring a clean and high-quality finish. TIG welding is highly regarded for producing precise, clean welds with minimal spatter.

TIG welding is commonly used in high-end applications such as aerospace, nuclear, and automotive industries where precision and weld integrity are paramount. It is ideal for welding thin materials and materials like aluminum, stainless steel, and copper alloys.

Comparing MIG and TIG Welding

Efficiency and Speed

When it comes to efficiency, MIG welding is the clear winner. The continuous feed of wire allows for faster welds, reducing the overall time spent on each joint. For projects where speed is a priority, MIG welding is often preferred.

On the other hand, TIG welding requires more skill and precision from the welder, and the process is slower because the filler material is manually added to the weld pool. TIG welding is best suited for situations where quality is more important than speed.

Quality of Weld

TIG welding is generally considered superior in terms of weld quality. The process produces cleaner, more aesthetically pleasing welds with minimal spatter. It also offers better control over the heat input, reducing the risk of warping or distortion.

MIG welding can still produce high-quality welds, but they tend to have more spatter and less precision than TIG welds. However, MIG welding is often sufficient for many industrial applications, where slight imperfections are acceptable.

Versatility and Material Compatibility

Both MIG and TIG welding can be used on a variety of materials, but TIG welding offers greater versatility in terms of the types of materials it can weld. TIG welding is ideal for thinner materials and metals like aluminum, magnesium, and stainless steel, while MIG welding is often better suited for thicker materials like steel and iron.

MIG welding is generally easier for beginners to master, making it more suitable for general-purpose applications. TIG welding requires greater skill and experience, but it is the preferred choice when working with specialized materials or for applications requiring precise welds.

Cost and Equipment

MIG welding machines are typically less expensive than TIG welding machines, making MIG welding a more cost-effective option for many applications. MIG welders are also easier to operate, reducing training costs and increasing overall efficiency.

TIG welding equipment is more expensive and requires more maintenance, but the precision and quality it offers make it an essential tool for high-end applications. The learning curve for TIG welding is also steeper, requiring more time and effort to master.

Ease of Use

For beginners, MIG welding is easier to learn and use. The continuous feed of wire reduces the amount of skill required to produce good welds, and the process is forgiving, making it ideal for people just starting in the field.

TIG welding requires more expertise, and the welder must manage the torch, filler material, and welding speed simultaneously. While this makes TIG welding a more complex skill to master, it also allows for greater control and precision.

Which Welding Process is Right for You?

When to Choose MIG Welding

MIG welding is ideal for applications where speed, ease of use, and cost-effectiveness are the primary concerns. It is well-suited for welding thicker materials, where precision is not as critical. If you need to weld on a production line or for general-purpose applications, MIG welding is likely the better choice.

When to Choose TIG Welding

If you require high-quality, precise welds with minimal spatter, TIG welding is the better option. It is the ideal choice for specialized projects that involve thinner materials or metals that require greater skill and precision. TIG welding is essential in industries like aerospace, automotive, and manufacturing, where weld integrity is of utmost importance.

Conclusion

Both MIG and TIG welding have their advantages and are suited to different applications. MIG welding is faster, easier to use, and more cost-effective, making it perfect for many industrial applications. TIG welding, while slower and more complex, offers superior precision and quality, making it essential for high-end projects. Understanding the specific requirements of your project will help you choose the right welding method for the job.